- Home

- Portfolio

Portfolio

Our Modular Concept

Module 0

Dust Collecting

Collecting the dust from all modules and leading them through a piping to a filter-system to separate the dust from air. This keeps the material and the working environment clean, to reach a good output quality and a healthy working environment.

Module 1

Goods receipt / sorting Floor

Quality assurance and transparency of material flow start here with the precise recording of weights when the goods are received. Large machines are removed from the flow of material.

Processing of the electronic scrap starts immediately on receipt of the goods. Complete loads and bulk material are weighed on the outdoor vehicle weighbridge. Packaged deliveries are recorded and weighed on the indoor vehicle weighbridge, assessed and then subjected to preliminary sorting. Both weighbridges are directly linked to our computer system. At the customer’s request, we are able to evaluate incoming deliveries. The material is sorted in accordance with the customer’s instructions and weighed using computer-aided platforms and belt weighing machines. This procedure ensures that the sorting criteria are met.

Module 1.1

Toner cartridges

Module 2

Preliminary breaking down

Breaking the material down into small pieces by a shredder, followed by separation into the fractions. Batteries and capacitors are separated from the process.

The rotating shredder breaks up electronic devices. The effect of the blows applied and of the items colliding with each other lead to the component parts of the equipment breaking off at the weakest points. For example, steel shafts are no longer cut up, but are only bent and torn from their mountings. Batteries and capacitors lose adhesion at the clamping or solder points. After being pulled out, the small parts are no longer able to absorb energy and can therefore leave the grinding room directly.

Large sheet-metal parts which do not pass through the outlet are processed further until they reach the size of the gap fitted.

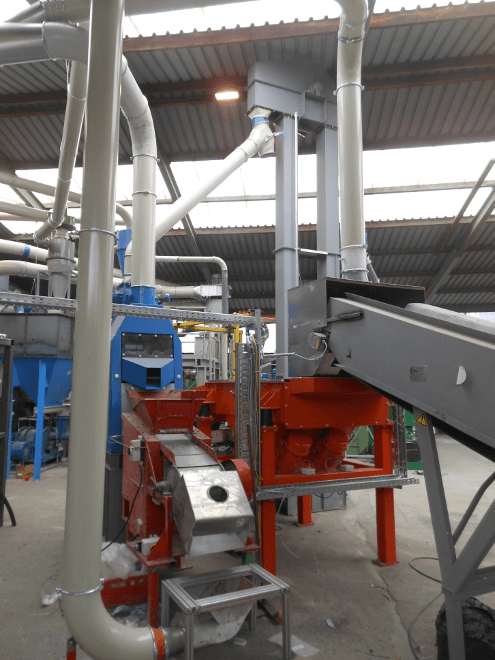

Module 3

Mechanical separation

Harmful substances and recyclable materials are separated out by means of magnetic separators, sieves, cyclone separators and manual sorting.

The dedusted material is separated into the >100 and <100 fractions by means of a fork-sieve.

Subsequent magnets, manual-sorting positions and cyclone separators ensure removal of harmful substances (batteries, capacitors) as well as separation of iron, aluminum, heavy metal and circuit-board fractions. The residual material is then again broken down and freed from dust.

The fractions in which the harmful substances have been concentrated are manually sorted out.

The fractions containing harmful substances which arrived from the mechanical sorting stages are sorted out manually via a silo with a dispensing delivery channel and a conveyor belt. In the process, recyclable materials such as brass, chrome-nickel steel and copper-iron are also picked out along with the harmful substances (batteries, capacitors).

Module 3.1

Extraction of plastics

None Ferrous, Mixed plastics and or PCB Boards is separated through none ferrous – and sensor system, which lead the plastic to Module 5.

Module 4

Fine Separation

Module 5

Plastic / Plastic Separation

Module 6

Refrigerator and Air conditioners

Module 7

Printed Circuits

Module 8

Cables

Knowledge Transfer, Education & Service (KES)

Regularly inspections

Ramp-up Production support

Trainings

Sales of Output Materials