- Home

- Services

Services

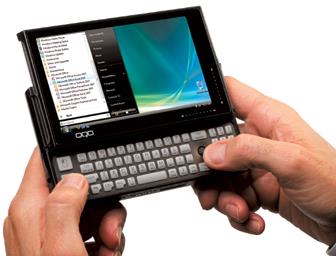

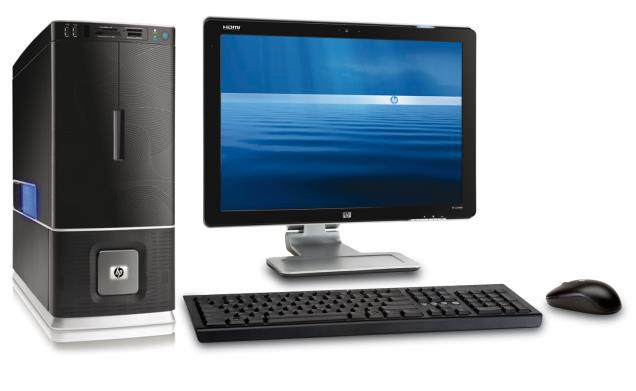

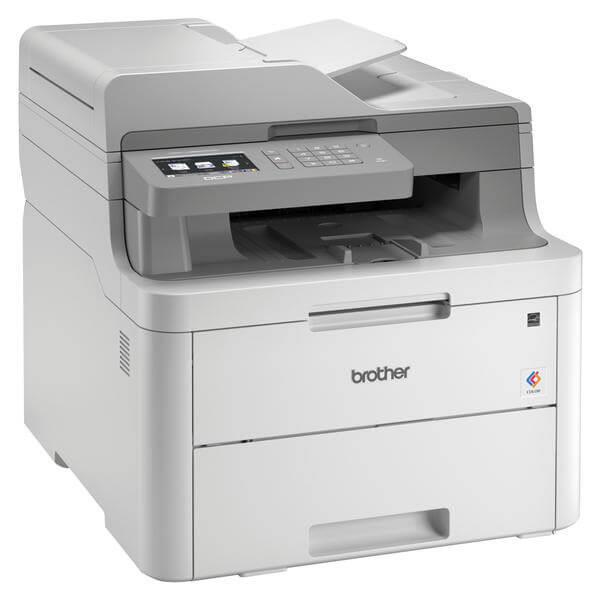

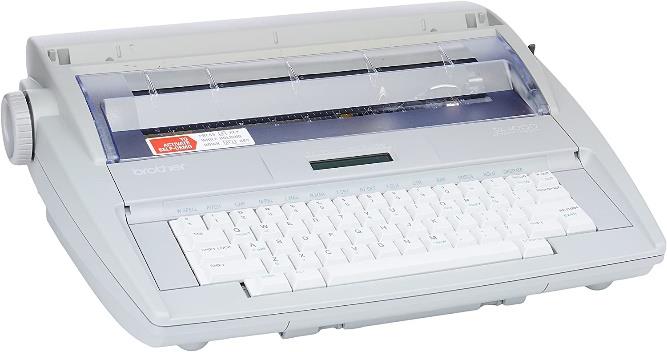

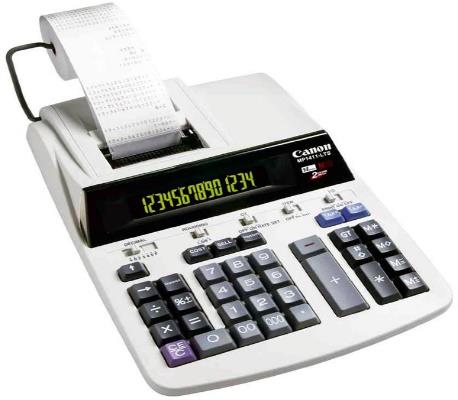

eWaste Recycling

Electronics waste, commonly known as e-scrap or e-waste, is the trash we generate from surplus, broken, and obsolete electronic devices. Electronics contains various toxic and hazardous chemicals and materials that are released into the environment if we do not dispose of them properly. E-waste or electronics recycling is the process of recovering material from old devices to use in new products.

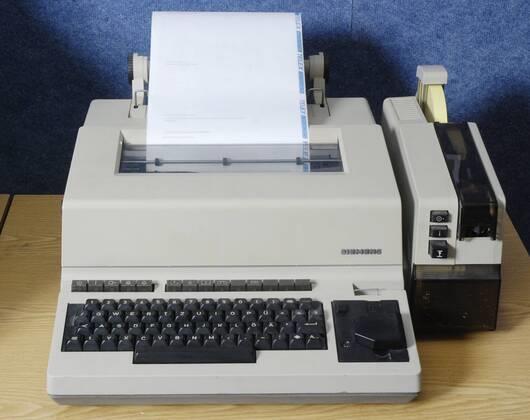

Data Destruction

To mitigate the potential hazards associated with the reuse or retrieval of data from corporate devices, Australian WEEE recycling practices employ physical destruction methods. These methods ensure the complete destruction of hard drives, cell phones, PDAs, tablets, tapes, flash memory, RAM, ROM, integrated circuits, DVDs, CDs, and computer equipment. By creatively implementing these measures, we can safeguard sensitive information and protect the privacy of individuals and organizations.

Collecting Ewaste

Recycling old electronics keeps this toxic waste from going to the landfill. It reduces the resources needed to make new ones.

Recycling eWaste

Technology is becoming more and more integrated into every aspect of our lives. Semiconductors and sensors are being added to products that never before had them, creating wearable monitors, smart homes, TVs that can stream programming from the internet, and much more.

Meanwhile, the life span of devices is getting shorter—many products will be thrown away once their batteries die, to be replaced with new devices. Companies intentionally plan the obsolescence of their goods by updating the design or software and discontinuing support for older models, so that now it is usually cheaper and easier to buy a new product than to repair an old one. Meanwhile, the companies continue to profit from steady sales. And because prices are dropping, electronic devices are in demand around the world as a growing middle class goes digital. Globally, half of all households now have internet access, and 7.7 billion people have cell phones.

Recycling Input Materials

Industrial eWaste

Telecom cable

We’re able to handle cables of all different types and grades

Waste Electrical and Electronic Equipment (WEEE), or e-waste, is one of the most rapidly growing forms of waste and a global problem. According to The World Counts, it’s estimated that over 50 million tons of e-waste is generated every year.

Broken and used telecom cables make up a troubling amount of e-waste in landfills and release toxins as they break down, harming the environment. It’s not something to ignore. Responsible cable reuse and recycling means that you can reduce your environmental impact while also generating revenue from the resale or recycling value.

How does telecom cable recycling work?

Our cable recycling solution puts cables back into use as either re-used parts or as materials for new products. All types of telecom cable are covered by this service including data, fibre optic, copper cables, coax (coaxial) cables, aluminium, lead coated and armoured.

Our service includes:

- Site clearance

- De-installation

- Recovery

- Resale (wherever suitable)

- Recycling

- Processing

- We are experts in recovering and recycling other forms of WEEE category 3: IT and telecommunications equipment too, such as printed circuit boards, back panels, motherboards, connectors and IC chips.

Turn your surplus cables into environmentally-friendly revenue

It’s always our aim to ensure that the highest proportion of revenue is generated from our clients’ excess cable. All while ensuring minimum waste to keep materials at the end of their life out of landfill. This makes precious metals available for repurpose, reducing the demand on primary sources.

As an approved authorised treatment facility (AATF) and approved exporter (AE), we maintain industry best practices for safe and responsible cable recycling. All of our activities are carried out in line with regulatory legislation. Please visit our certifications page for more details.

- Benefits of our telecom cable recycling services

- Rapid investment recovery and convenience

- Detailed commodity breakdown by weight

- Large quantities of cables recycled

- Other legacy surplus equipment can be recovered at the same time

- Experienced with switch dilapidation and exchange dilapidation

- All processes are fully compliant with the WEEE Directive

We hold a full environmental permit and waste carrier’s license.

Starting Soon

Solar Panel

With the average lifespan of a solar panel at roughly 20 years, installations from the early 2000s are set to reach end-of-life. Will they end up in landfill or be recycled? The cost of recycling is higher than landfill, and the value of recovered materials is smaller than the original, so there’s limited interest in recycling. But given the presence of heavy metals, if waste is managed poorly, we’re on track for another recycling crisis.

The presence of hazardous materials in the end-of-life solar panels can result in significant pollution and health issues, if released into the environment. To close the loop in the energy cycle, the next mission of the solar panel industry is the safe disposal or recycling of end-of-life products. In the waste management hierarchy, however, re-use or value-added recovery/re-purposing is considered preferable to recycling.

The main contributor to the total weight of a typical crystalline silicon PV module is glass (75%), followed by polymer (10%), aluminum (8%), silicon (5%), copper (1%) and small amounts of silver, tin, lead, and other metals and components. Lead and tin, if leached into soil and groundwater cause health and environmental concerns, while copper, silver, and silicon present a value opportunity if recovered efficiently. So, the landfill option should be fully replaced with recycling to prevent environmental pollution and retrieve the valuable materials present in the panel.

Refrigerant

Shredder Floc Management

Shredder Floc Management

This program supported new approaches to managing metal waste (shredder floc) produced during recycling.

We acknowledge the Traditional Custodians of country throughout Australia and their connections to land, sea and community. We pay our respect to their Elders past and present and extend that respect to all Aboriginal and Torres Strait Islander peoples today.